You're currently on:

Manufacturing process

Logs are cut twice a year, in spring through summer

and in fall through winter.

The bark being removed from felled timber.

As you can see, this process is done by hand,

one log at a time.

Each piece of lumber is shaped into the main koto body

(the ryuko).This is a body we produced this year.

As you can see, the wood is still white in tone.

Surface filing

Carving out the inside

Measuring the weight of each piece and making small

adjustments to file it down

Zig-zag carving

Carefully carved, leaving no point overlooked

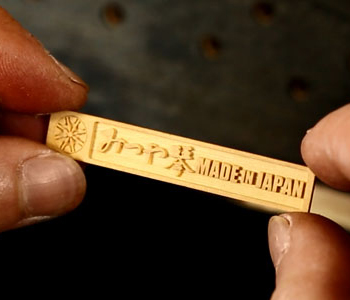

The Hidemitsu and Toshimitsu hallmarks are the

marks of an original Mitsuya Koto article.

Heat treating the surface

The entire surface is evenly heated.

Under the hands of our skilled craftsmen,

the unique wood grain,

a Mitsuya Koto signature, is brought to the surface.

Installing parts

Installing the end caps

Installing parts Installing the decorative kashiwaba.

It is treated with lacquer.

Finishing

Installing feet

MITSUYA KOTO MADE IN JAPAN

Stay up to date

informationcontrol

my accountcontrol

Chinese

Chinese English

English  Japanese

Japanese